Restoration of a 200-year-old Schwieso Grecian Concert Harp

Business Need

Our client Ian Bartlett, a private collector and restorer of antique musical instruments, initially approached a professional instrument restorer for help with a 200-year-old Schwieso Grecian concert harp, crafted primarily from brass. He was quoted £1,500 for the cleaning alone.

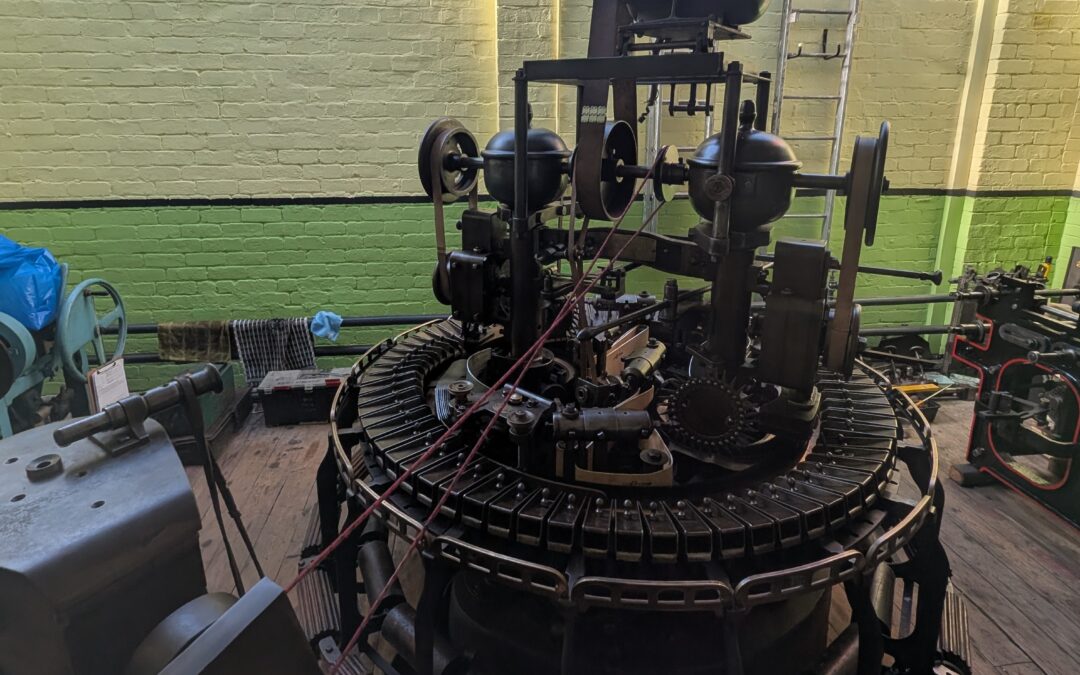

Seeking a more cost-effective but equally careful solution, he reached out to Sonic Solutions, trusting our reputation as industrial cleaning specialists to handle the delicate restoration of this rare artifact — one of only around 900 ever made.

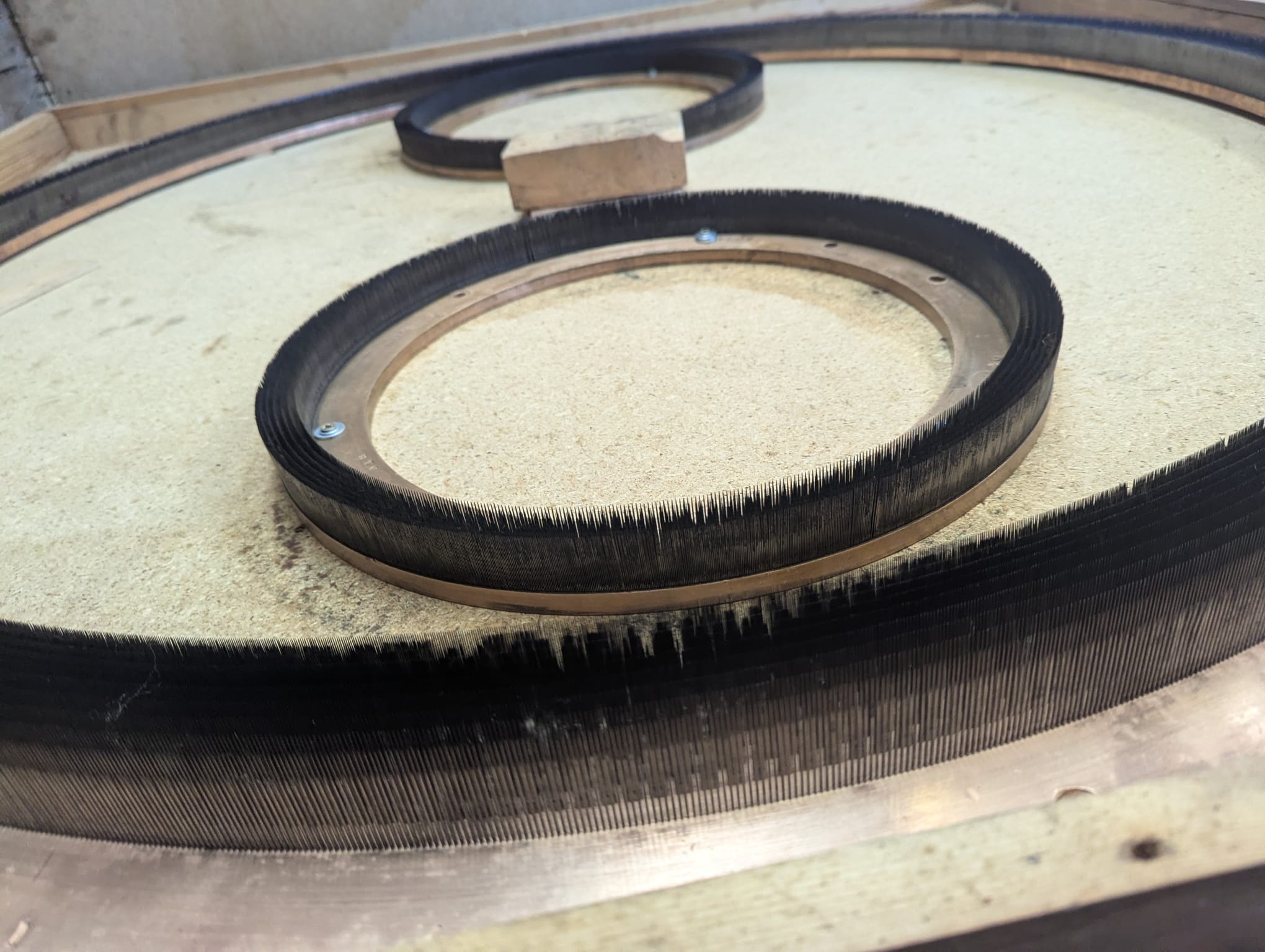

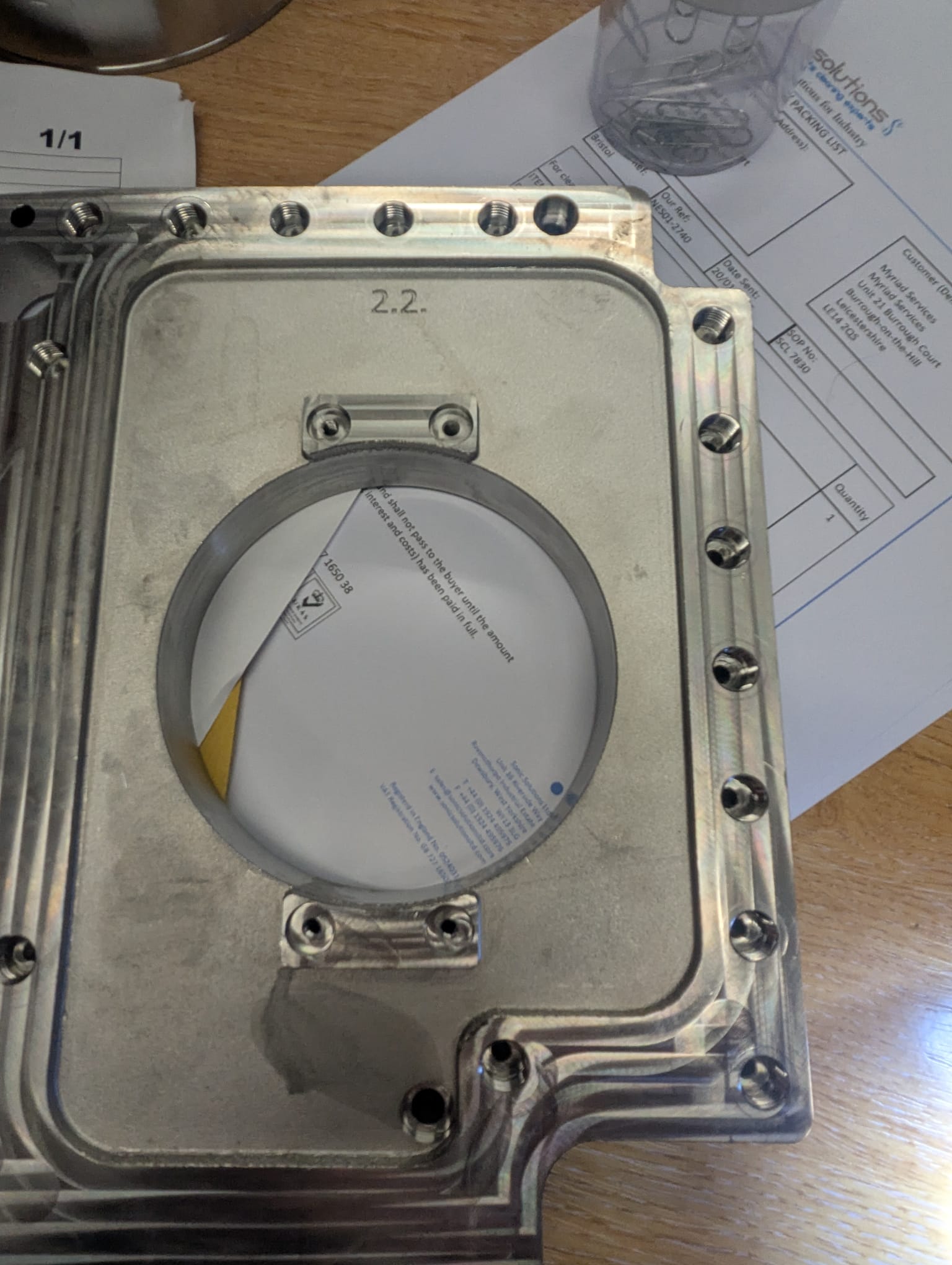

The harp was heavily tarnished and corroded due to centuries of exposure, with surface contaminants that required removal without damaging the original metalwork or intricate detailing.

Our Role

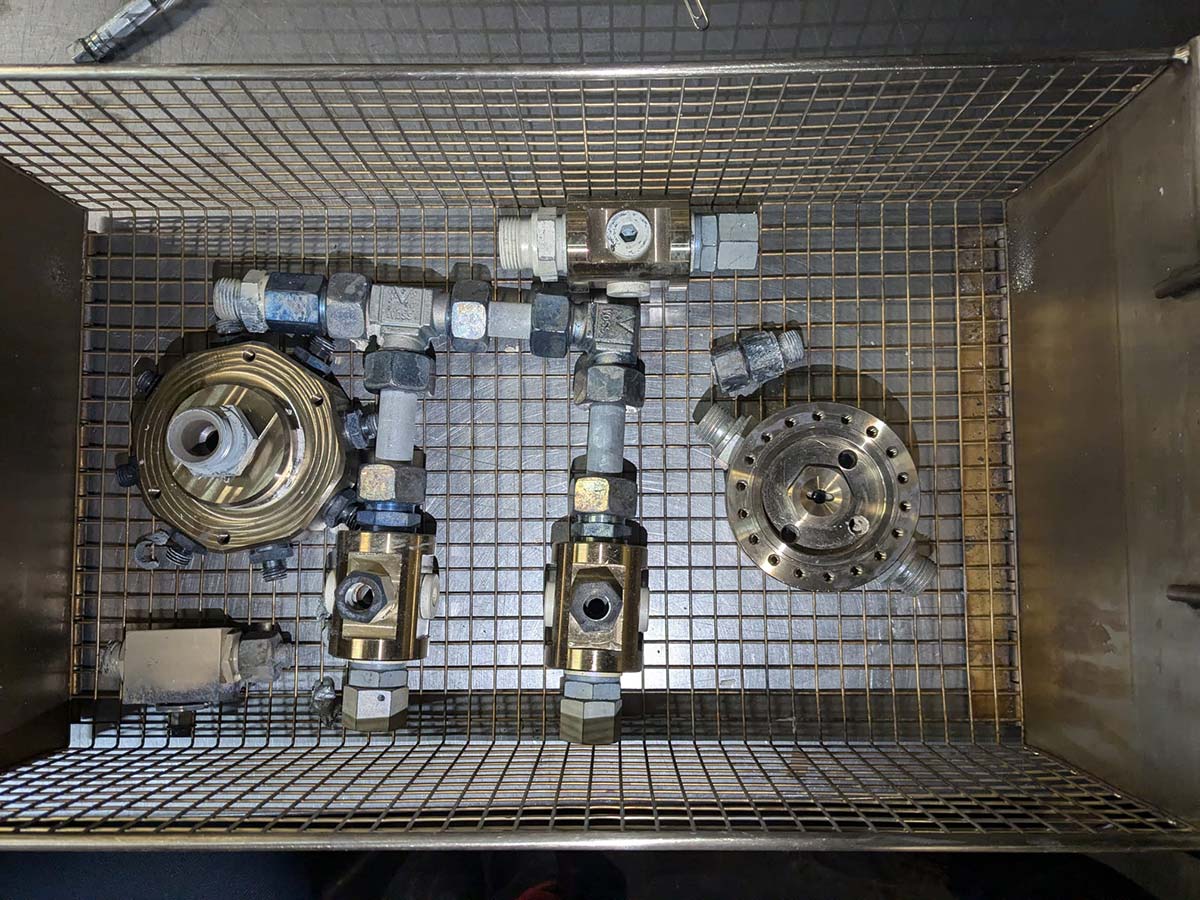

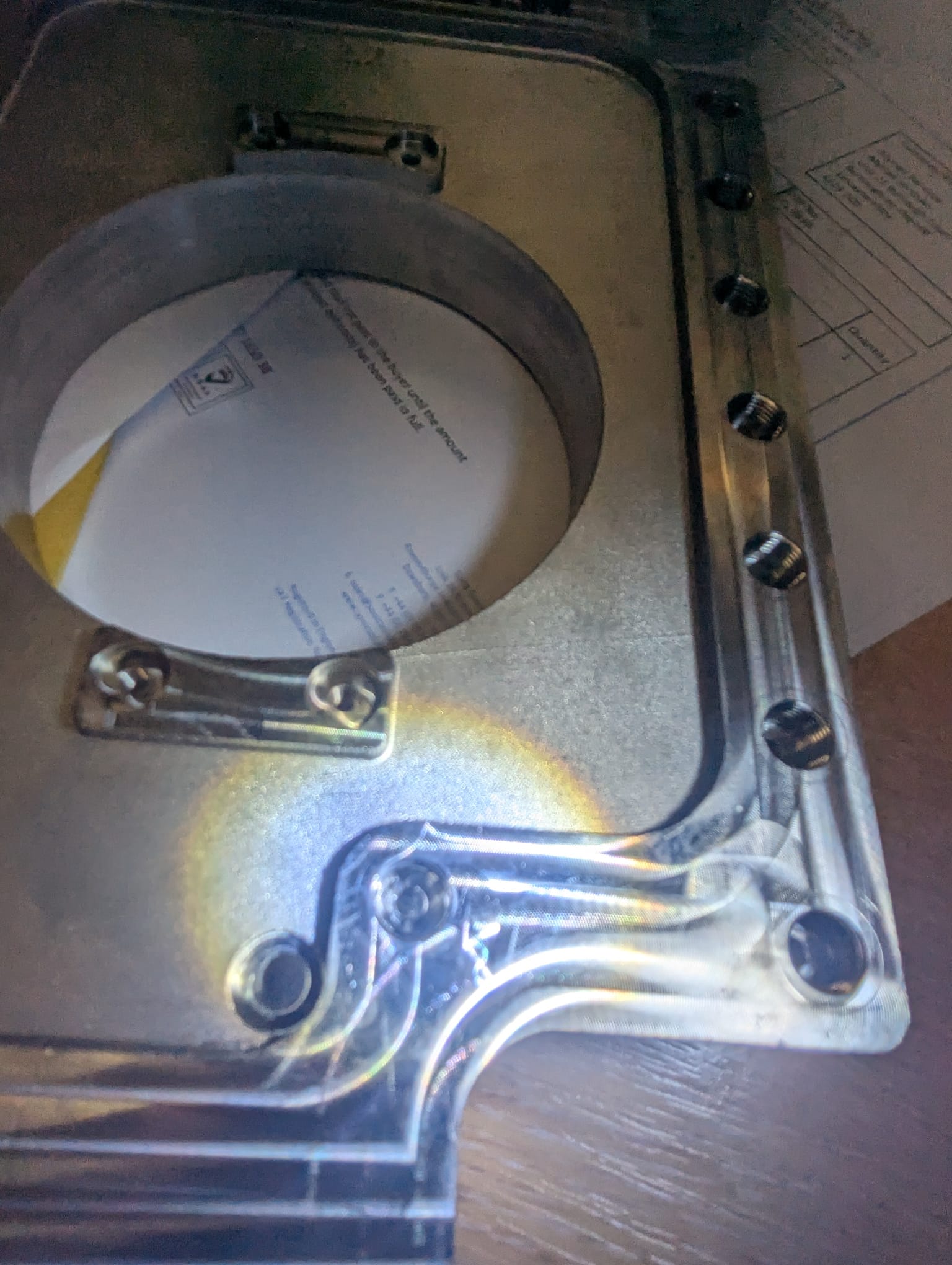

We designed a bespoke two-step cleaning process tailored to the harp’s brass components. First, we applied a controlled acid treatment to break down oxidation and corrosion from the surface, safely revealing the underlying brass without aggressive abrasion.

Then, using our ultrasonic cleaning technology, we gently removed all loosened residues and contaminants from the detailed brasswork and delicate fittings. This method ensured a deep, thorough clean while protecting the harp’s structure and craftsmanship.

The Outcome

The restoration revealed the original brilliance of the brass and preserved the fine historical details of this rare musical instrument. The client was delighted to have the harp cleaned and stabilized for just £350 — a significant saving compared to the £1,500 quoted by traditional restorers.

Our work provided a museum-quality result at a fraction of the cost, ensuring this unique piece of history can now be appreciated for generations to come.