Specialist Cleaning Solutions for One of the UK’s Leading Automotive Manufacturers

For friendly & knowledgable help contact us on:

01924 495 975 hello@sonicsolutionsltd.com Open Contact Form

Business Need

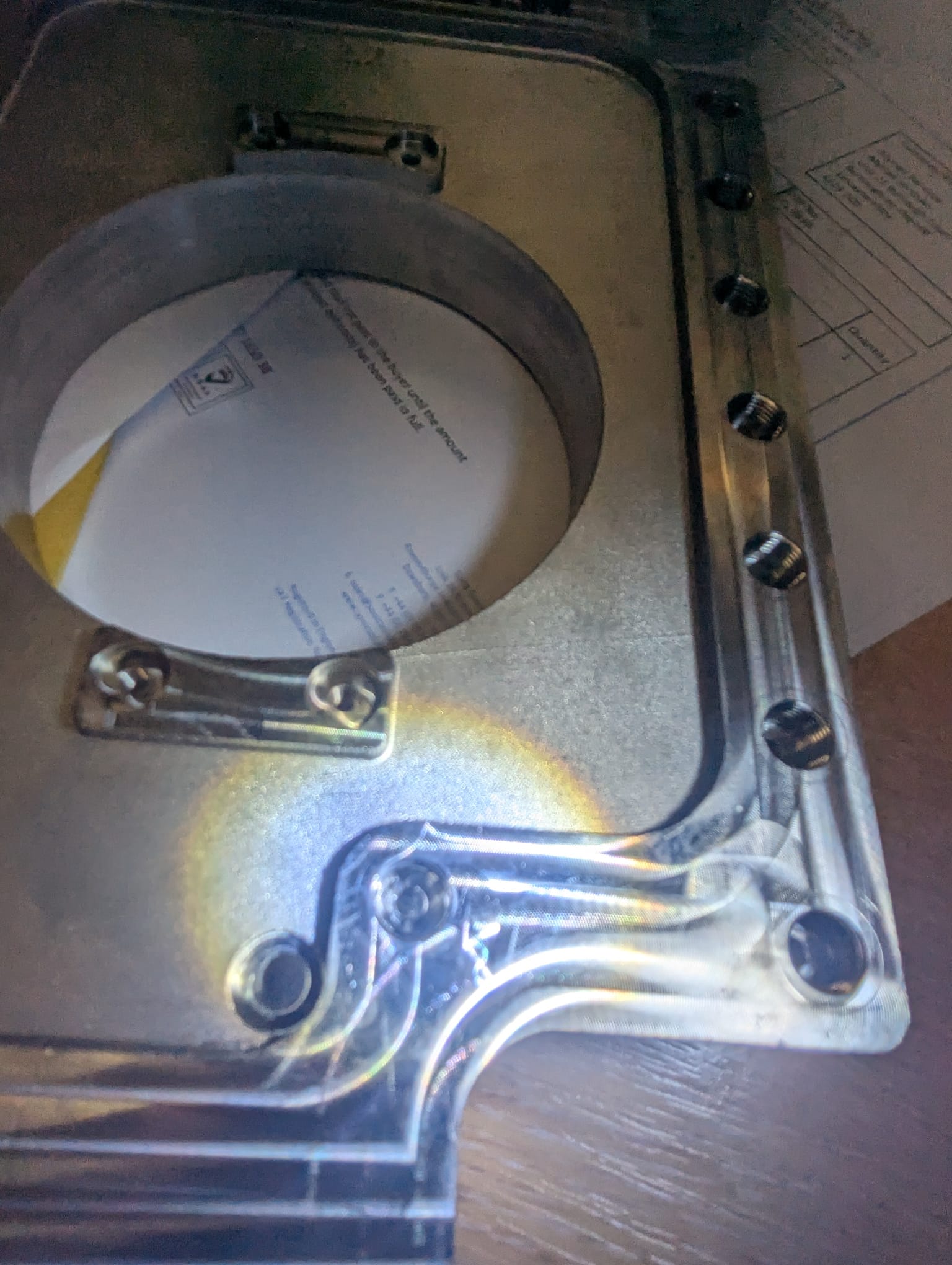

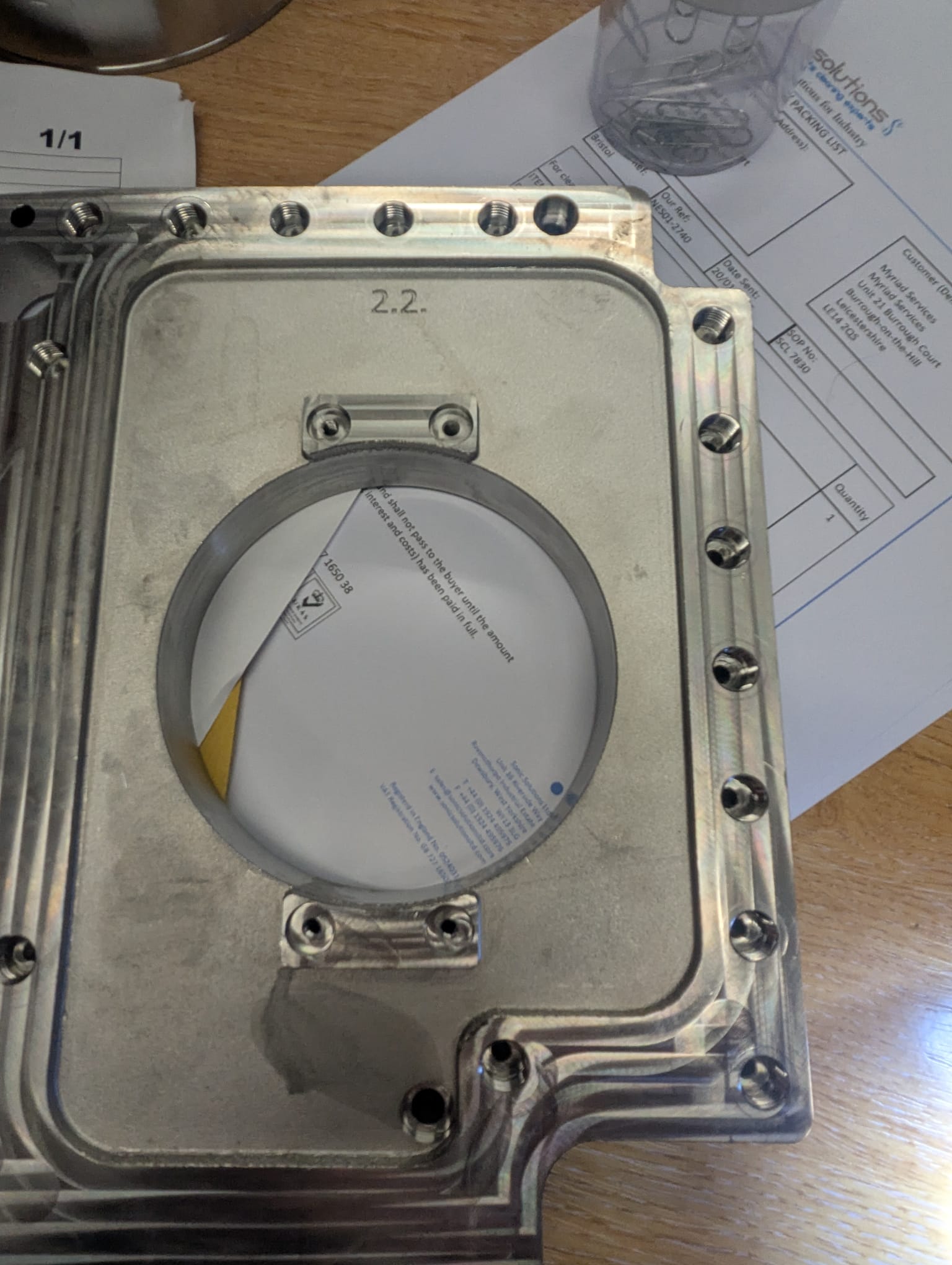

A leading automotive manufacturing facility required a specialist solution for cleaning metal components contaminated with adhesive. Initially, the task involved removing adhesive from various metal parts. However, due to the success of our approach, the company later engaged us to clean small silicon busbar housings covered with hardened adhesive. The challenge was to carry out these delicate cleaning processes without damaging the components while ensuring a safe and controlled environment.

Our Role

To address this issue, our team implemented a precise and controlled cleaning process:

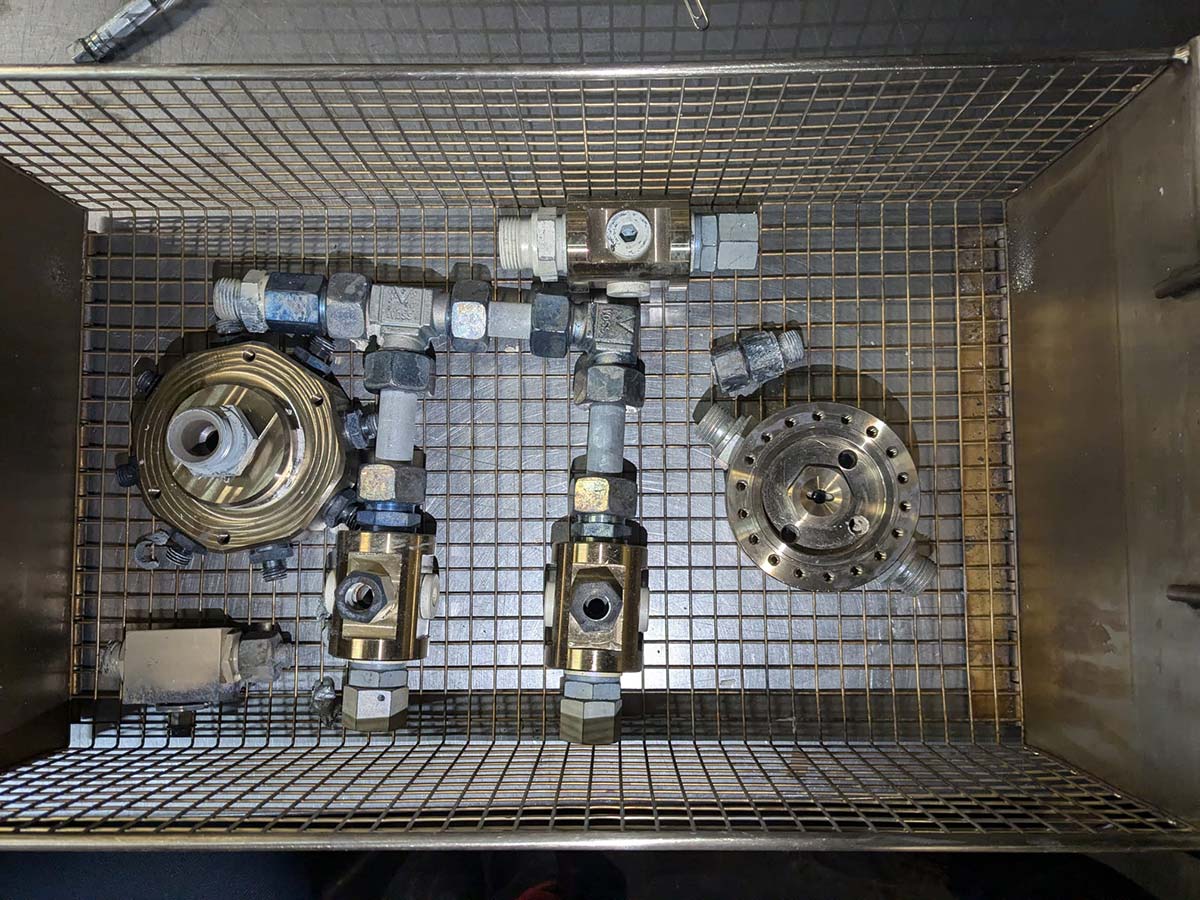

- Acetone Soaking & Ultrasonic Cleaning: We developed a two-stage process where metal parts were soaked in acetone and then ultrasonically cleaned in the same solution.

- Explosive Risk Mitigation: Given the flammable nature of acetone, we maintained strict monitoring throughout the ultrasonic cleaning process to prevent ignition risks.

- Silicon Busbar Housing Cleaning: As the project expanded, we introduced new methods to remove hardened adhesive from delicate silicon busbar housings, ensuring their integrity while achieving a thorough clean.

- Quality Control & Safety Measures: All cleaning procedures were carefully monitored to ensure the components remained undamaged, and our team followed stringent safety protocols to prevent any hazardous incidents.

The Outcome

The completion of this project resulted in:

- Successful removal of adhesive contaminants without damaging the metal or silicon components.

- A refined cleaning process that ensured all parts were restored to optimal condition.

- Increased client trust, We have now seen more jobs from our happy client, further evidencing their faith in our ability.

- Strict adherence to safety protocols, preventing any incidents while working with volatile cleaning agents.