Industrial Cleaning of Heat Exchangers, Cleaner Systems, Better Performance

For friendly & knowledgable help contact us on:

01924 495 975 hello@sonicsolutionsltd.com Open Contact Form

Business Need

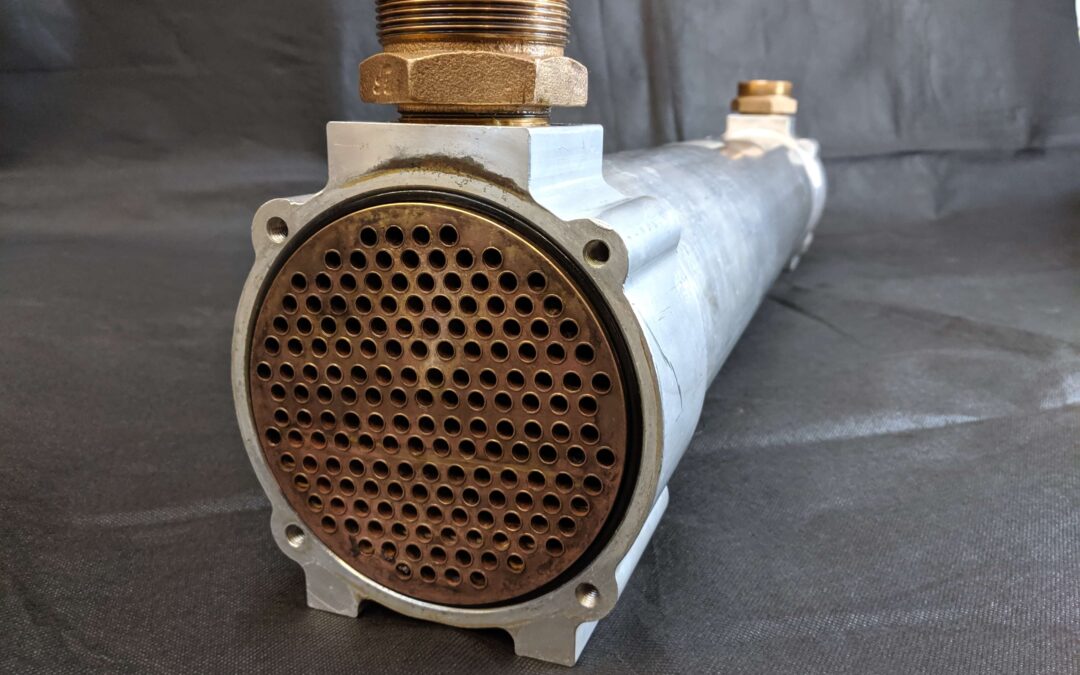

Heat exchangers are vital to industries ranging from energy and manufacturing to food processing and HVAC. But over time, even the most robust systems suffer from scale build-up, fouling, and contamination that reduce efficiency and increase running costs.

A range of clients recently approached Sonic Solutions for help maintaining and restoring their heat exchangers. In each case, operational performance was being compromised by internal deposits, from stubborn mineral scale to baked-on hydrocarbons.

Time was a critical factor. Cleaning needed to be fast, thorough, and safe, with minimal disruption to the client’s schedule.

Our Role

Using tailored ultrasonic cleaning methods, we removed hard deposits and fouling from even the most awkward internal surfaces. Our systems reach deep into tubes and crevices that traditional cleaning can’t, without the need for disassembly or aggressive chemicals.

Whether working with small precision units or large industrial-scale heat exchangers, our approach delivered consistent, high-quality results.

The Outcome

In every case, the cleaned heat exchangers were returned to service with improved thermal efficiency, extended lifespan, and lower risk of unplanned downtime. Clients reported measurable performance improvements and reduced maintenance overheads.

From preventative maintenance to emergency restoration, Sonic Solutions delivers the cleaning power heat exchangers need, with no mess, no damage, and no delays.