Ultrasonic Cleaning of Anilox Rollers in the Print Industry

For friendly & knowledgable help contact us on:

01924 495 975 hello@sonicsolutionsltd.com Open Contact Form

Business Need

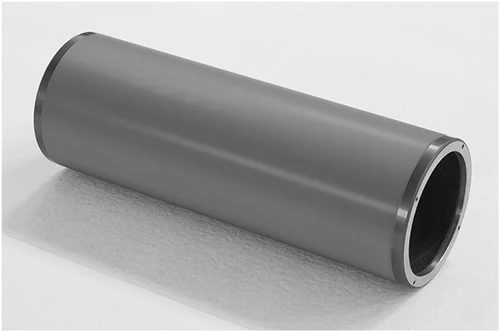

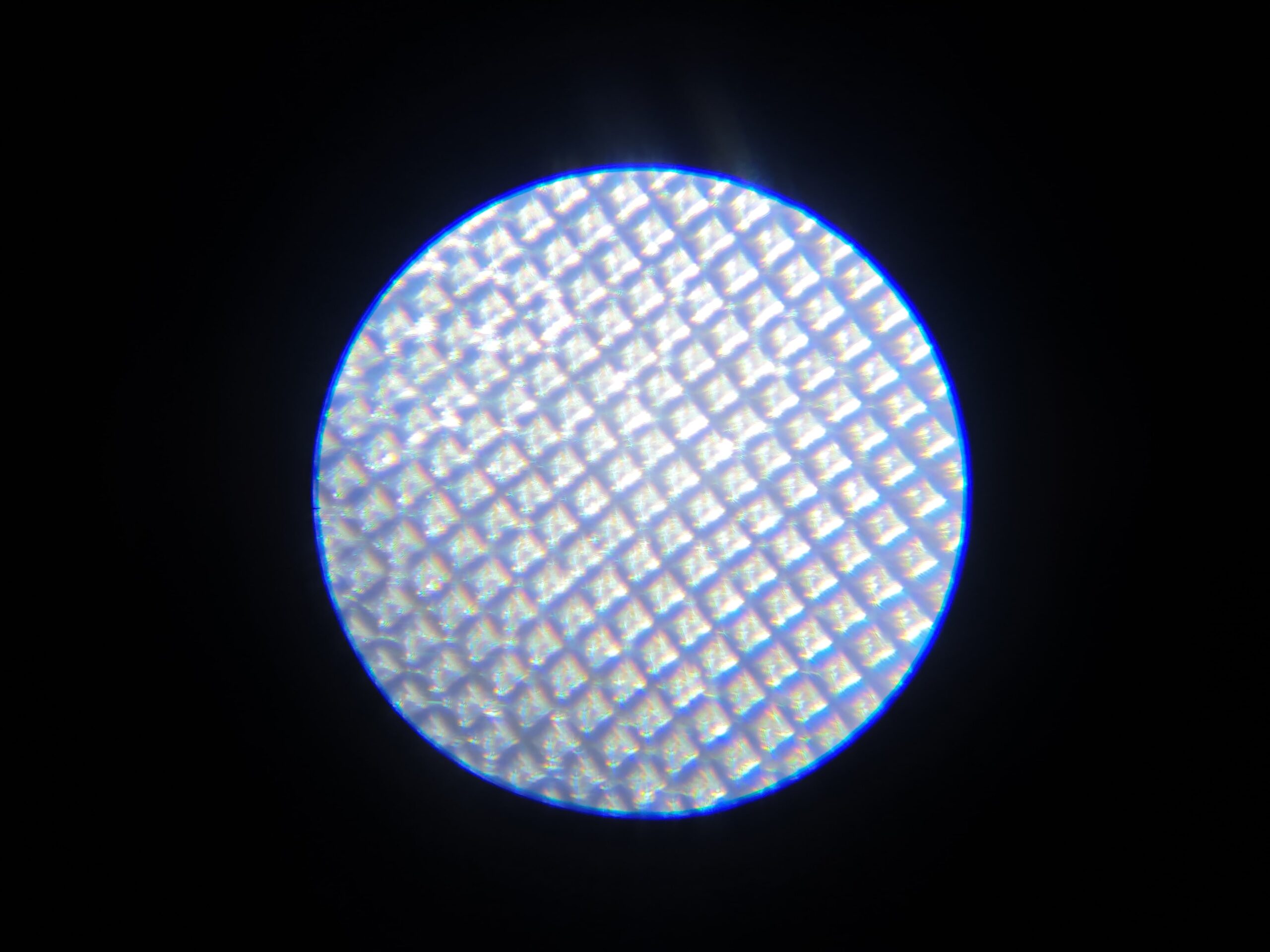

Anilox rollers are critical to delivering consistent, high-quality print results. Over time, ink and coatings become trapped deep within the roller cells. While a roller may look clean to the naked eye, microscopic inspection often reveals residues that compromise performance.

One of the UK’s largest plastic bottle manufacturers recently faced a challenge: a sleeved anilox roller due for repair required precision cleaning. Unlike traditional rollers, sleeved rollers don’t include the side mechanisms that normally support them, making the job far more complex.

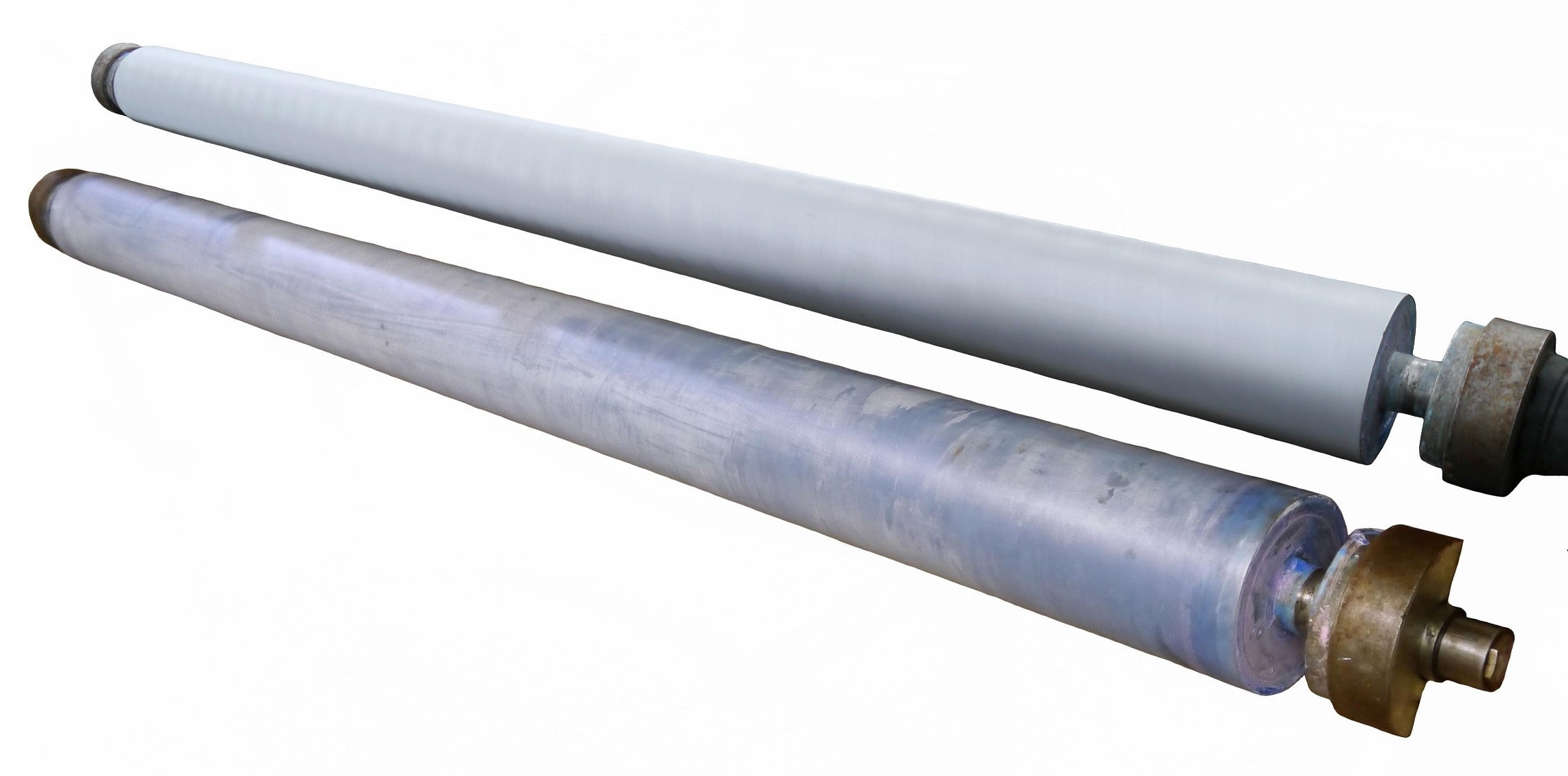

With many years of experience cleaning rollers from 30 cm up to 5 m in length, our team brought both skill and adaptability to the task. We applied our proven 5-step cleaning process:

- Chemical coat to loosen hardened deposits

- Ultrasonic cleaning to penetrate deep into microscopic roller cells

- Internal flush to clear contaminants from within

- Rinse and rub for a controlled, residue-free finish

- Careful packaging to ensure the roller was protected during transit

Despite the missing support hardware, we engineered a safe, effective method for the sleeved roller and executed each step with precision.

The Outcome

The result was a roller that was not only visibly spotless but also validated under microscopic inspection, proving it was fully cleaned and ready for repair. This successful outcome reaffirmed our ability to handle even the most unusual and demanding roller-cleaning projects.

Client Testimonial

“We were impressed with the precision and care shown in cleaning our sleeved roller. The ultrasonic process gave us complete confidence that the roller was ready for repair—saving us time and ensuring production quality down the line.”

— Senior Production Manager, UK Plastic Bottle Manufacturer

📞 Want to work with us? Get in touch today!