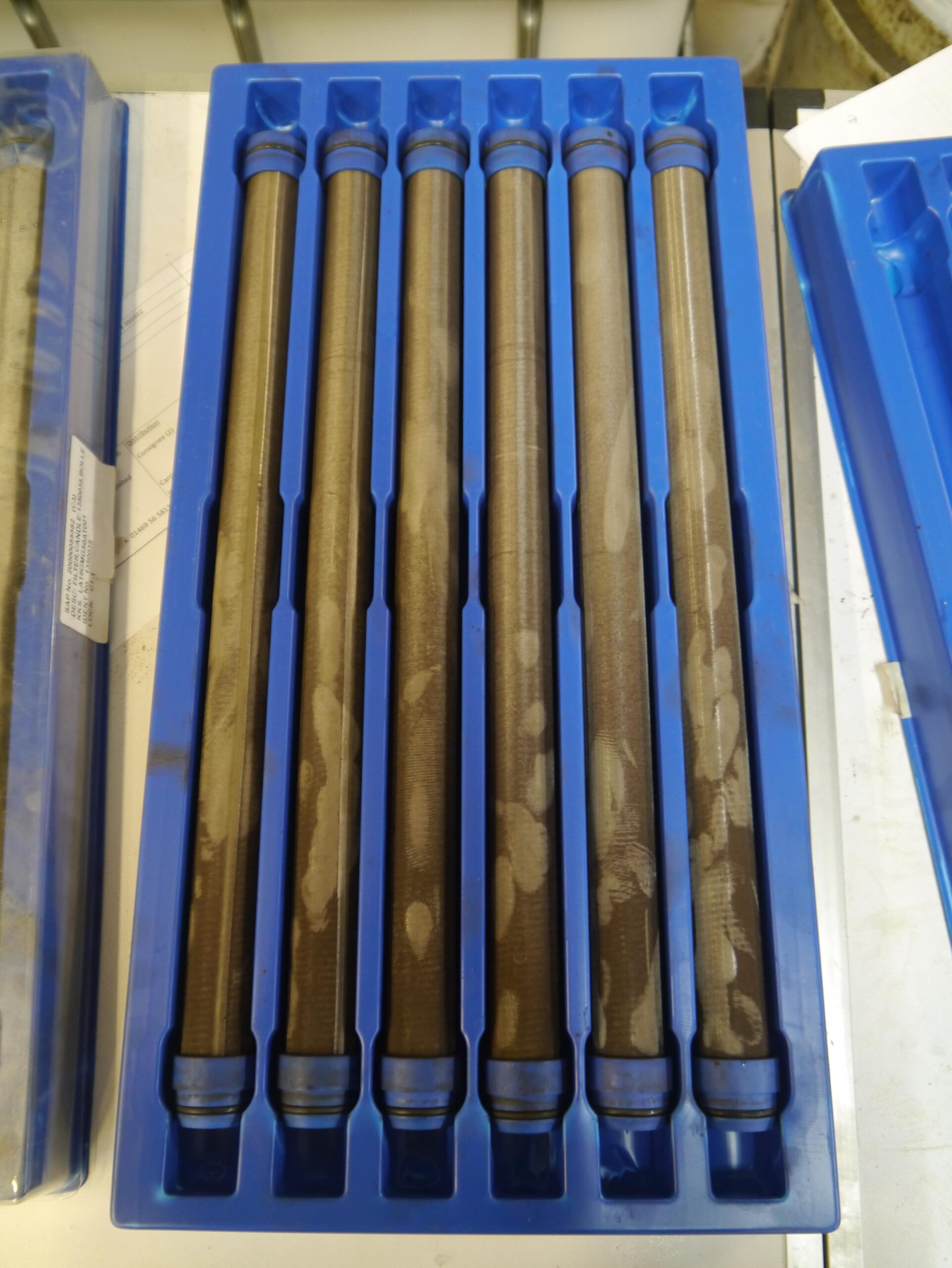

Deep Clean, Clear Flow – Candle Filters Restored

For friendly & knowledgable help contact us on:

01924 495 975 hello@sonicsolutionsltd.com Open Contact Form

Business Need

Candle filters are essential for maintaining system performance, but over time they become clogged with stubborn contaminants, this is most commonly heavy carbon buildup and particulate debris.

This fouling restricts flow, reduces filtration efficiency, and forces equipment to work harder, leading to higher maintenance costs and increased risk of downtime.

Our Role

We applied our ultrasonic cleaning techniques with a combination of carefully picked chemicals to restore the filters to optimal condition. The filters were placed in the tanks with slight agitation, where high-frequency sound waves create microscopic bubbles that implode against the surface of the filter elements.

This cavitation action safely but effectively breaks down and removes carbon deposits and embedded contaminants, The filters have deep channels within them but this is not a problem for our ultrasonic cleaning methods as we were able to get them spotless inside and out.

The Outcome

Following ultrasonic cleaning, the candle filters were transformed from clogged and inefficient to crystal clear and fully operational. The restored filters provided improved flow and filtration performance, extended the service life of the equipment they protect, and significantly reduced both downtime and ongoing maintenance costs.

Instead of costly replacements, our customer achieved spotless results through our service proving that regular parts cleaning is cheaper, faster and more efficient than buying new