Ultrasonic Cleaning vs Media Blasting

For friendly & knowledgable help contact us on:

01924 495 975 hello@sonicsolutionsltd.com Open Contact Form

Ultrasonic cleaning and media blasting are two very different cleaning methods, though can be used for similar applications. Here at Sonic Solutions, we specialise in ultrasonic cleaning, but we do have a wet media blaster that can aid in some cleans.

How they work

Ultrasonic cleaning – This uses high-frequency sound waves in solution to create microbubbles that implode on the surface of the item to create a sucking action that lifts dirt from the surface. This is incredibly good at fine cleaning and reaching internal parts that would otherwise be missed by manual cleaning. Read our full rundown of how ultrasonic cleaning works here.

Media Blasting – Fires media (usually glass beads or aluminium oxide) at high pressure to remove contaminants through abrasion. This is especially efficient at removing thicker contamination such as heavy grease or rust. Some media blasters also use high-pressure water as well as media (such as the one we have here at Sonic Solutions) Which leaves a much shinier finish on the surface, especially with aluminium parts.

How we use them

If we received an item, some classic car parts for example, how would we clean them? In the past, before we invested in our media blaster, we would use only ultrasonics for this. We may give them an initial jetwash to try remove the thick of the grease and oil but most of the cleaning action is down to the chemical and ultrasonic power. The problem with this is that it can take an incredibly long time to remove thick contamination so we could be working on one item for two days in some situations.

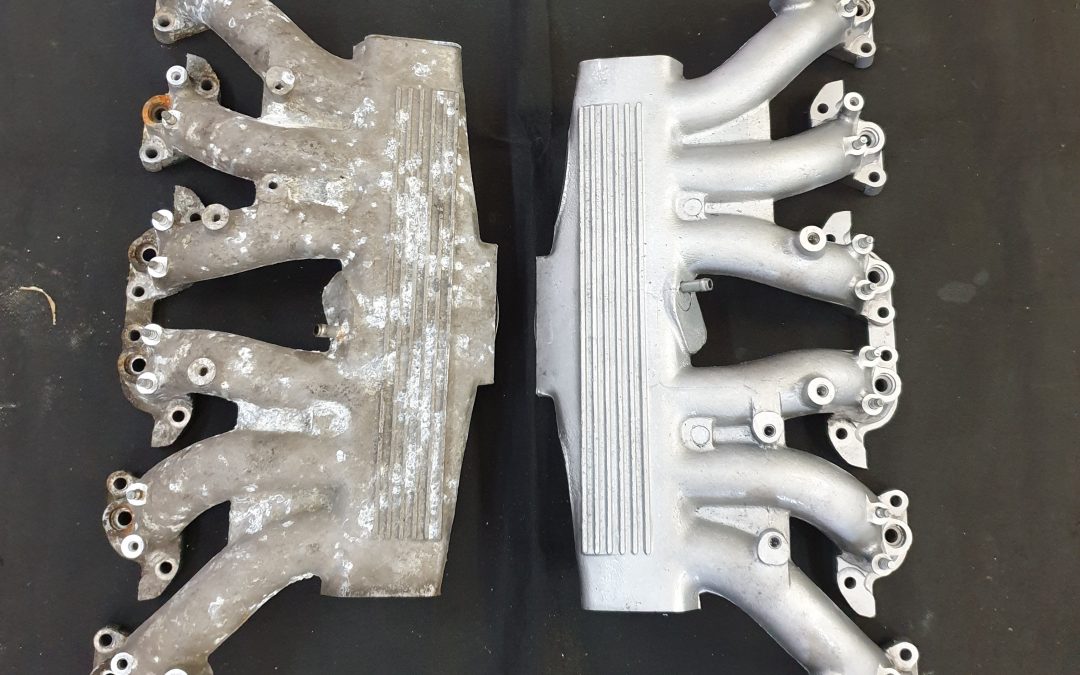

Nowadays, with our wet media blaster on hand, we use both cleaning methods together to aid cleaning. We would begin by putting the items through our media blaster to get rid of the thick of the contamination on all the outside parts that are accessible. Once we have removed as much as we can, we would then place the item into an ultrasonic bath with the appropriate chemistry to remove any contamination from internal chambers and hard to reach nooks and crannies.

Even if the media blaster managed to remove all the contamination, we would still put the items through an ultrasonic bath to remove any of the media that has gotten onto the item. If the part was aluminium and we wanted to keep it looking shiny after the media blast, we would ultrasonically clean them in denim water to remove the media whilst keeping the shine.

Most media blasting companies will just hose down an item once they have blasted it to get rid of the media residue. Although this works good enough for most customers, there is always the chance that some of it will be left in small apertures which may cause issues down the line.

To summarise, both cleaning methods have their advantages and strengths, but we believe that a combination of both can provide an unparalleled clean that could not be achieved using one process alone.

To understand more about ultrasonic cleaning and how it might benefit you and your application please call or email one of our helpful cleaning experts today on 01924 938052 or hello@sonicsolutionsltd.com