What is the burning issue? Sonic Solutions diversify and here is what we’re doing…

For friendly & knowledgable help contact us on:

01924 495 975 hello@sonicsolutionsltd.com Open Contact Form

It has been an interesting couple of months at Sonic, and indeed for most of the world! Apart from surviving Covid-19 (so far !!) we are proud to announce that we now offer a pyrolysis/Burn-off/thermal stripping service, which will allow us to serve you EVEN better. More on this subject later. For those who don’t know what pyrolysis is I will try to explain what it is, and more importantly what benefits it gives you.

What actually is Pyrolysis? 🤔

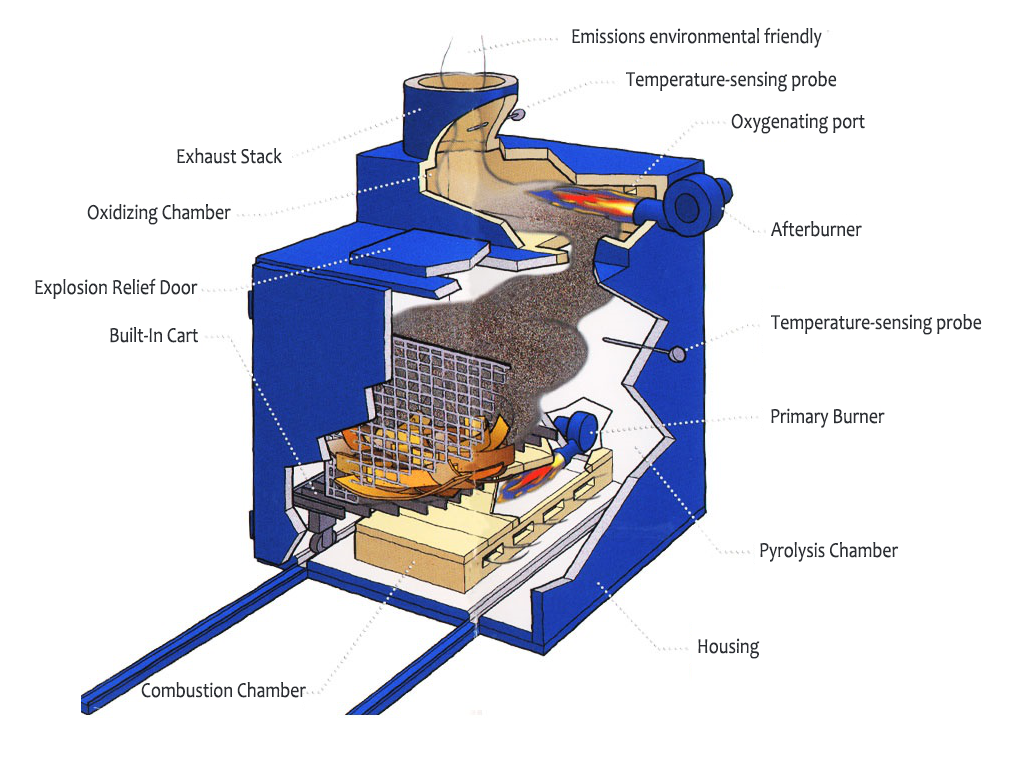

Pyrolysis is the thermal decomposition of materials at temperatures between 310 and 540 C (depending on the contaminant to be removed) in an inert, oxygen-deprived atmosphere. Undergoing this process organic substances like paints and plastics are decomposed to produce volatile organic compounds, hydrocarbons and a solid inert ash residue. These volatile products and hydrocarbons are then reduced to inert gases and vapour through exposure to temperatures of 700 to 900 C in an “afterburner” normally placed on top of the pyrolysis oven. The solid ash residue is normally either left on the floor of the oven or lies on the surface of the item and can be easily removed through jet washing or ultrasonic cleaning.

What benefits does burning give? ✅

Where heavier metals need to have coatings of paints, polymers or plastics removed it is a far quicker, safer, cheaper and more effective way of bringing them back to bare metal than the alternatives of chemical and abrasive treatments. The controlled rise, holding and then reduction in temperature over an extended period in the absence of oxygen reduces the risks of combustion and the stresses on the metal due to rapid expansion and contraction. This means the coating is completely removed WITHOUT DAMAGING the item itself.

What can burning actually clean? 🔥

Pyrolysis is typically used to clean products or production components like extruders, spinnerets, static mixers, pipes, valves, even rejected parts that need re-coating, that are coated in paints, polymers or plastics such that they cannot perform their function.

So…what next?

We will be releasing more information over the coming weeks regarding our new service, helping us serve you better for years to come. Sonic Solutions are the UK’s leading ultrasonic cleaning service and following our extension of cleaning services to include jet washing and vapour blasting we are now offering thermal cleaning 👍.

For any queries or questions regarding pyrolysis please don’t hesitate to get in touch with us on 01924 495 975 or e-mail Andrew on andrew@sonicsolutionsltd.com